After:Ceramics

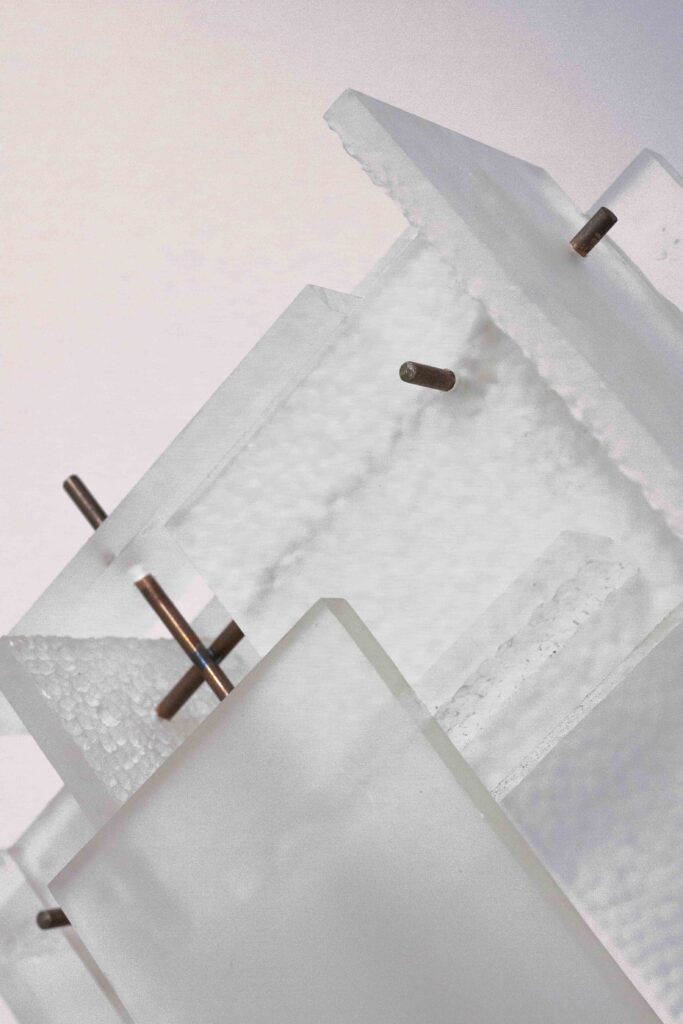

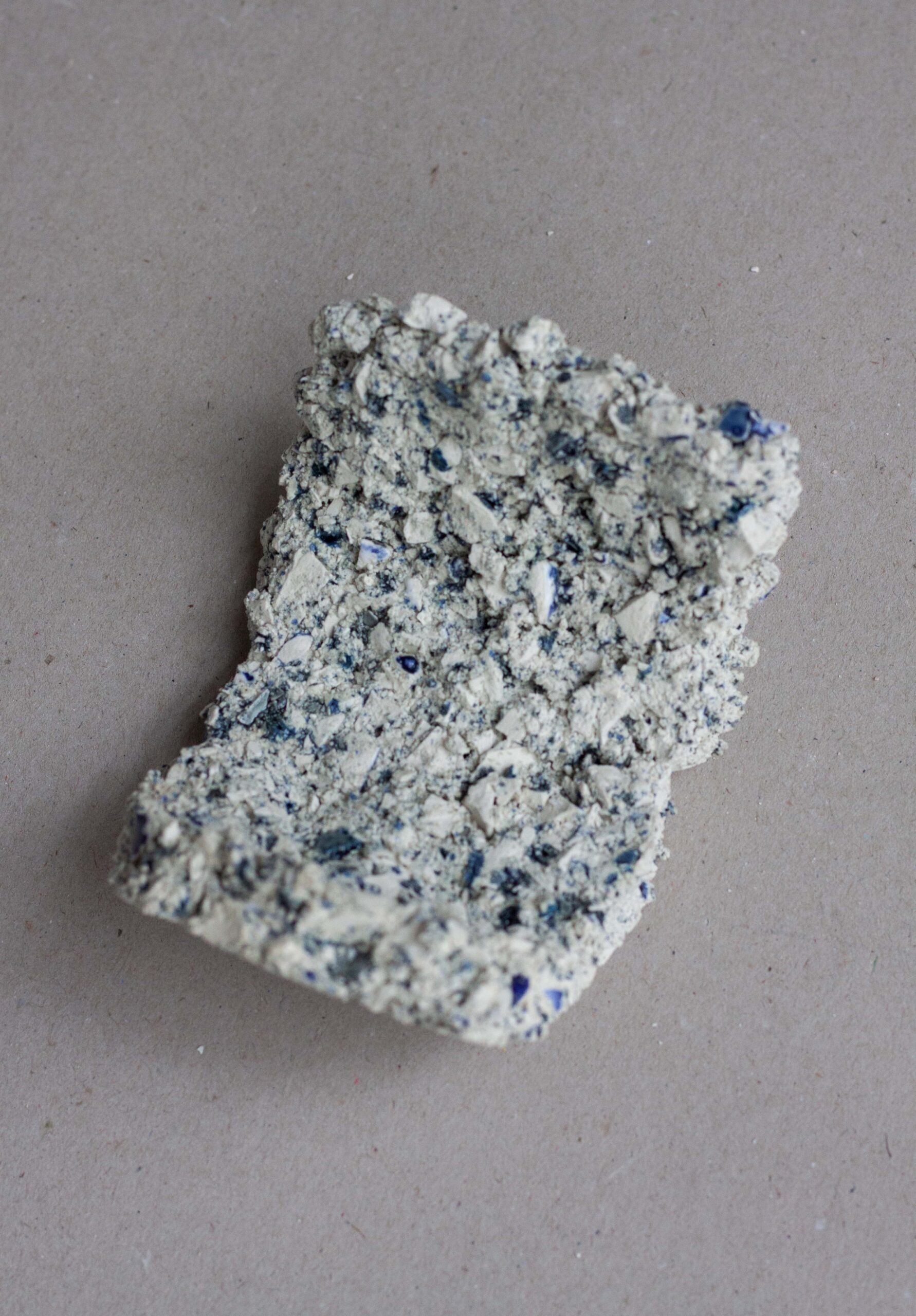

Tichelaar spend hours on researching finding the perfect glaze and tiles of making hundreds of test before the find the final one. With this proces there is a lot of passion and dedication and this reflects in the final product that is given to their client. Because of the high quality standard within the factory a high percentage of their production in discarded as waste.

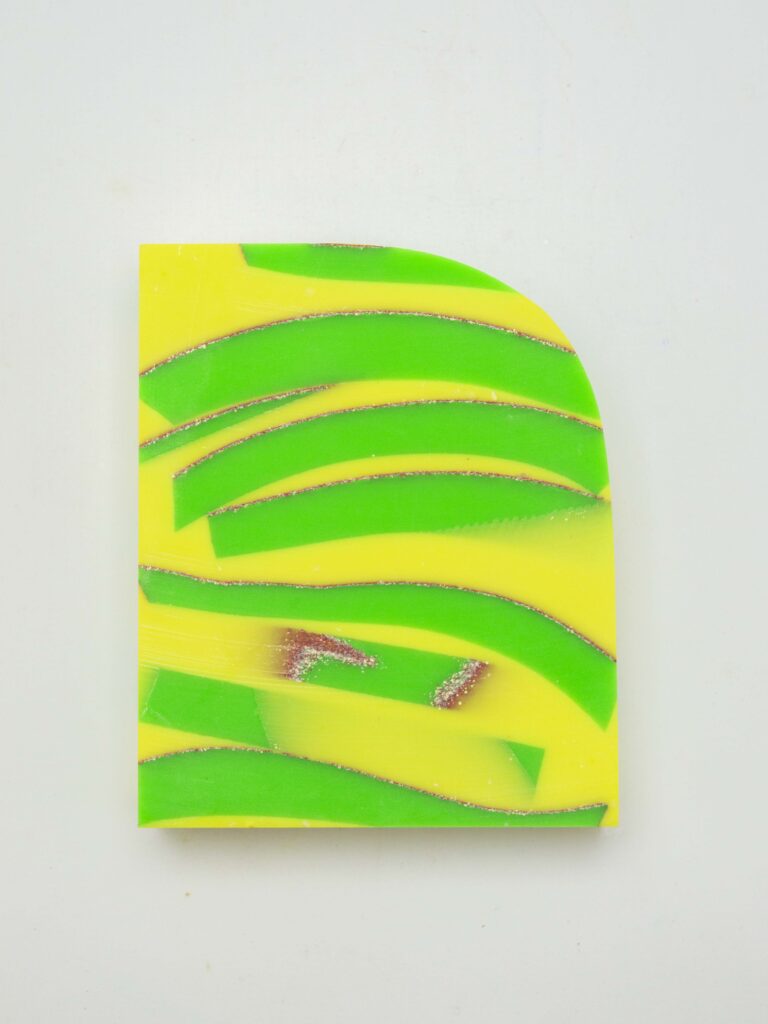

The times that we are living in cost of raw materials is rising and are becoming more valuable. With ceramics and especially glaze a lot of valuable minerals are used, for now a lot of these minerals are hard to recycle in isolating it to a virgin material.

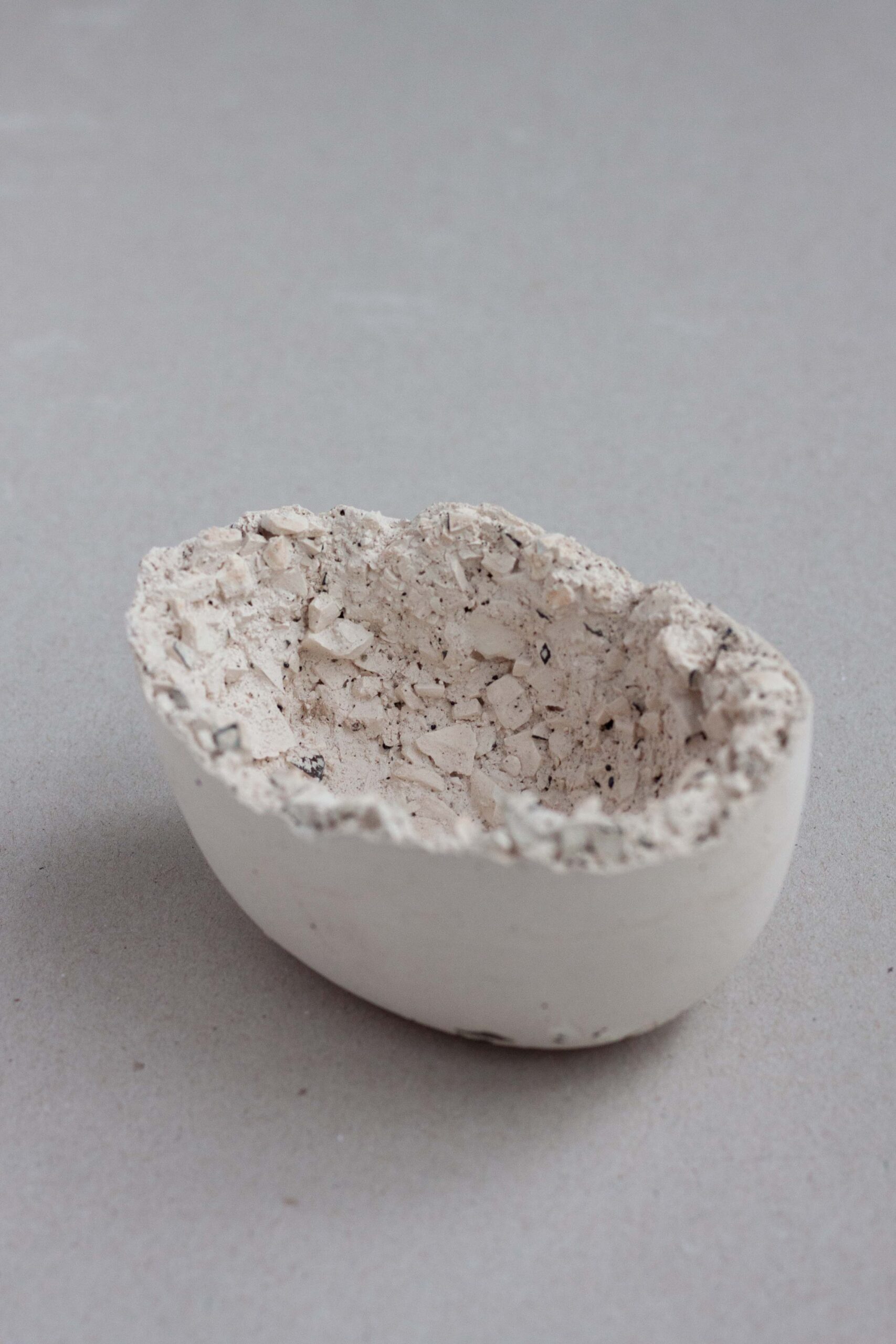

In the project I wanted to embody the waste and its impurities. Using all the types of waste that is created within the factory, creating a recipe for a material that is applicable and unique to every new project that enters the factory.